EB

y Heise helps the plastics industry to

achieve greater efficiencies through the

following set of services:

Blow

mold & tool design |

| Our

blow mold design capabilities range from the

digitizing of models or cavities to complex

3D modeling from simple sketches or from bidimensional

drawings using our computer aided design software

SDRC I-Deas, Delcam and Pro/ENGINEER. |

|

Endorsed

with a huge mold design data base and more than

three decades of experience in the design of

molds, our engineering personnel is recognized

as the best in the industry. All our molds are

designed to operate to the fastest cycles possible

and to produce articles with exact dimensions.

We are always improving our productivity and

manufacturing processes to offer an excellent

product at a fair price.

Computer

Aided Bottle Design

In product development and mould design we offer

you:

2D and 3D

Computer Aided Design

Solid modeling

Plastic bottle

design

Volumetric calculation

Productivity

optimizing Mold design .

|

|

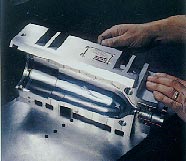

EB-Heise

has great experience in the manufacture of an

ample variety of molds for different blow molding

materials and processes. We have produced a great

variety of molds for plastic products, from light

containers for the dairy industry to great size

industrial applications, from simple molds to

very complex molds with irregular partition lines

and movable parts, we have the knowledge and experience

required to satisfy your needs.

We

have adopted high speed machining processes to

our plants and are committed with our clients

to offer molds with the best quality in the industry.

Allow EB-Heise to show you machined cavities with

so perfect finishing that we have almost eliminated

the necessity of polishing them by hand. Our dimensional

consistency of cavity to cavity is by far the

best one of the industry.

|

Our

full-time quality control inspectors evaluate

the different components of the molds throughout

the manufacturing process and after the final

assembly.

We measure, register and store all the criticall

dimensions for future use. |

Our

inspection department is equipped with Cordax

CMM's, optical comparators, special gauges

and a whole lot of precision instruments to

assure precise and complete inspections. Each

mold that we make goes through a leak test

on its cooling system and an evaluation of

coolant flow to assure that it fulfills the

high standards established by our engineering

department.

|

|

|

| |

|